Industrial sector, and among its shining achievements is the production of Custom Molded Rubber Shapes In Valencia and products. These items are fundamental to countless applications across various industries, including automotive, aerospace, healthcare, and consumer goods.

In this article, we’ll explore why Valencia has become a hub for these specialized rubber products, how they are made, their diverse applications, and how you can benefit from sourcing your rubber needs here.

What Are Custom Molded Rubber Products?

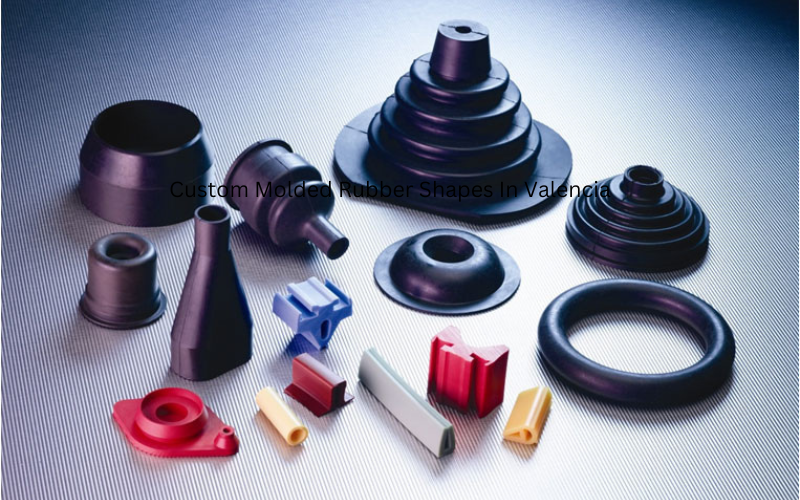

Custom Molded Rubber Shapes In Valencia are items tailor-made to specific sizes according to the needs of a customer. The process involves shaping rubber into detailed configurations, which can range from simple washers and seals to complex components used in machinery and electronics. The flexibility of rubber molding allows for high precision and versatility, making it ideal for custom applications.

Why Valencia for Rubber Products?

Expertise and Innovation

Valencia boasts a wealth of experience in rubber manufacturing, with numerous companies specializing in this field for decades. This long-standing expertise ensures that products are not only of high quality but also incorporate the latest advancements in rubber technology. Manufacturers in Valencia continually invest in research and development, pushing the boundaries of what can be achieved with rubber.

Advanced Manufacturing Capabilities

The use of cutting-edge technology in Valencia’s manufacturing plants allows for precision in rubber molding that is hard to match. Facilities are equipped with modern machinery that can handle various types of rubber compounds and complex mold designs. This technology ensures that each product meets strict specifications with consistent quality.

Customization at Its Best

Valencia’s rubber manufacturers stand out for their ability to customize products to exact customer specifications. Whether you need a unique compound for increased heat resistance or a specific design to meet intricate assembly requirements, manufacturers in Valencia can accommodate almost any demand. This high level of customization is supported by skilled engineers and designers who work closely with clients to ensure their needs are precisely met.

The Process of Rubber Molding

The production of custom molded rubber products involves several key steps:

-

Design and Prototyping: The process begins with detailed drawings and specifications provided by the customer. Using these, the manufacturer designs a mold. Prototypes may be created to ensure the design meets all functional requirements before full-scale production begins.

-

Mold Creation: A mold is crafted from metal, usually steel or aluminum, to form the cavity that will shape the rubber.

-

Rubber Compounding: Rubber compounds are formulated to achieve desired properties such as elasticity, resistance to temperature, and durability. This mixture is then processed into a state ready for molding.

-

Molding: The rubber compound is placed into the mold and subjected to heat and pressure. This causes the rubber to cure and take the shape of the mold. Techniques like injection molding, compression molding, or transfer molding may be used depending on the product.

-

Finishing: After molding, the products are trimmed of any excess material, inspected for quality, and prepared for delivery.

Applications of Custom Molded Rubber Products

The versatility of custom molded rubber products makes them indispensable in various sectors:

- Automotive: Used in gaskets, seals, hoses, and anti-vibration components.

- Aerospace: Components that must withstand extreme conditions, such as seals and insulation parts.

- Medical: Non-reactive seals and components used in medical devices.

- Consumer Products: Everything from household appliance components to waterproof cases.

How to Source Custom Molded Rubber Products from Valencia

Identify Potential Manufacturers

Start by researching manufacturers in Valencia that specialize in custom molded rubber products. Look for companies with strong reputations for quality and service.

Discuss Your Requirements

Contact these manufacturers to discuss your specific needs. Be prepared to provide detailed specifications and quantities. It’s helpful to know the properties you need in your rubber product, such as temperature resistance, flexibility, or electrical conductivity.

Evaluate Prototypes

If possible, request prototypes to evaluate the quality and functionality of the rubber products. This step is crucial for ensuring that the final product will meet your requirements.

Visit Facilities

Consider visiting the manufacturing facilities if feasible. This visit can provide insight into the capabilities and quality control measures of the manufacturer.

Place Your Order

Once satisfied with the prototypes and the manufacturer’s capabilities, you can confidently place your order.

Conclusion

Custom Molded Rubber Shapes In Valencia dedication to quality, innovation, and customer satisfaction. With advanced manufacturing capabilities and extensive experience, Valencia is ideally positioned to meet diverse and demanding rubber product needs. Whether you require small or large volumes, simple shapes or complex configurations, sourcing your custom molded rubber products from Valencia ensures you receive components that meet the highest standards of excellence. Thank visiting logicallyblogs.com