Stainless steel cable ties, also known as SS cable ties, are versatile fastening devices used for bundling, organizing, and securing cables and wires in various applications. These ties are crafted from high-quality stainless steel, offering exceptional strength, durability, and resistance to corrosion. In this discussion, we’ll explore the features, applications, advantages, and considerations associated with stainless steel cable ties.

Features of Stainless Steel Cable Ties:

Stainless steel cable ties boast several features that make them suitable for a wide range of applications:

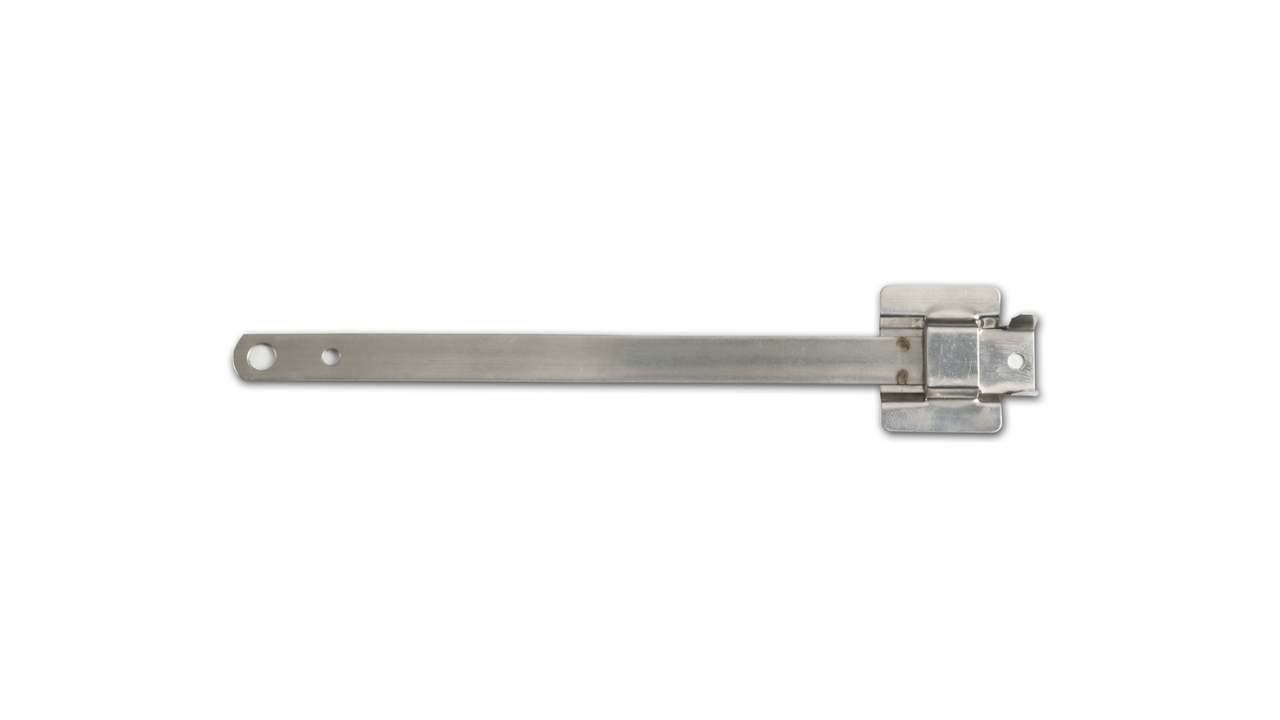

Material: Constructed from marine-grade stainless steel, these cable ties exhibit superior resistance to corrosion, chemicals, and extreme environmental conditions, making them ideal for outdoor and harsh industrial environments.

Strength: Stainless steel cable ties are known for their high tensile strength, providing reliable support and secure fastening of cables, hoses, pipes, and other objects. They can withstand significant mechanical stress without compromising performance.

Durability: With their robust construction and resistance to UV radiation, moisture, and temperature fluctuations, stainless steel cable ties offer long-lasting durability and stability, ensuring reliable cable management over extended periods.

Adjustability: Many stainless steel cable ties feature a ball-locking mechanism or self-locking design, allowing for easy adjustment and secure fastening without the need for additional tools. This facilitates quick and efficient installation in various applications.

Applications of Stainless Steel Cable Ties:

Stainless steel cable ties find applications across diverse industries and environments, including:

Industrial Settings: In industrial facilities, stainless steel cable ties are used for bundling and securing cables, wires, and hoses in machinery, equipment, and control panels. They provide reliable support and organization, reducing the risk of cable damage and ensuring efficient operation.

Marine and Offshore: In marine and offshore environments, stainless steel cable ties are essential for securing cables, pipes, and components exposed to saltwater, humidity, and harsh weather conditions. They offer corrosion resistance and durability, making them suitable for shipbuilding, offshore platforms, and marine installations.

Telecommunications: Stainless steel cable ties are employed in telecommunications infrastructure for securing fiber optic cables, coaxial cables, and communication lines. They provide a stable and secure mounting solution for aerial cables, reducing cable movement and signal interference.

Construction and Infrastructure: In construction projects and infrastructure installations, stainless steel cable ties are used for cable management in buildings, bridges, tunnels, and utility poles. They help organize and secure electrical, HVAC, and plumbing systems, ensuring proper routing and protection of cables and conduits.

Advantages of Stainless Steel Cable Ties:

Stainless steel cable ties offer several advantages over other fastening methods:

Corrosion Resistance: Stainless steel cable ties are highly resistant to corrosion, rust, and degradation, making them suitable for outdoor and corrosive environments where conventional cable ties may deteriorate over time.

High Strength: With their robust construction and high tensile strength, stainless steel cable ties provide secure and reliable fastening of heavy cables and components, minimizing the risk of cable slippage or detachment.

Temperature Resistance: Stainless steel cable ties can withstand extreme temperatures ranging from -80°C to 538°C, ensuring stability and performance in both freezing cold and high-temperature environments.

Reusable: Unlike plastic cable ties, stainless steel cable ties are reusable and can be easily unfastened and repositioned as needed, allowing for flexible cable management and maintenance.

Considerations for Use:

When using stainless steel cable ties, it’s essential to consider the following factors:

Proper Sizing: Select stainless steel cable ties with the appropriate length and width to accommodate the diameter and weight of the cables or objects being secured. Avoid over-tightening, as this can cause damage to the cables or components.

Installation Technique: Use the correct installation technique to ensure secure fastening and proper tensioning of the cable ties. Avoid sharp edges or abrasive surfaces that may damage the stainless steel coating during installation.

Environmental Conditions: Consider the environmental conditions and exposure levels when choosing stainless steel cable ties. For applications in highly corrosive or hazardous environments, select stainless steel grades with enhanced corrosion resistance, such as 316 stainless steel.

Maintenance: Periodically inspect stainless steel cable ties for signs of wear, damage, or corrosion. Replace any damaged or degraded cable ties to maintain optimal performance and reliability.

Conclusion:

Ss cable ties are indispensable components for secure and durable cable management in various industries and environments. With their exceptional strength, durability, and resistance to corrosion, stainless steel cable ties provide a reliable solution for bundling, organizing, and securing cables, wires, and components. By understanding their features, applications, advantages, and considerations for use, engineers, technicians, and installers can effectively utilize stainless steel cable ties to ensure efficient and reliable cable management in diverse settings.